Personal Protective Equipment – Hand Protection

Personal Protective Equipment – Hand Protection

Explain dangers

The best tools we have are our hands. We need to protect them on the job.

Manual work exposes our hands to many different hazards, from cuts to chemicals, from pinching to crushing, and from blisters to burns.

Identify controls

Leather gloves provide good protection against sharp edges, splinters, and heat. Cotton or other materials don’t stand up well. You should wear them only for light-duty jobs.

Wearing anti-vibration gloves when using power tools and equipment can help prevent hand-arm vibration syndrome (HAVS).

HAVS causes the following changes in fingers and hands:

• Circulation problems such as whitening or bluish discoloration, especially after exposure to cold

• Sensory problems such as numbness and tingling

• Musculoskeletal problems such as difficulty with fine motor movements—for instance, picking up small objects.

Workers who use vibrating tools such as jackhammers, grinders, riveters, and compactors on a daily basis may develop HAVS.

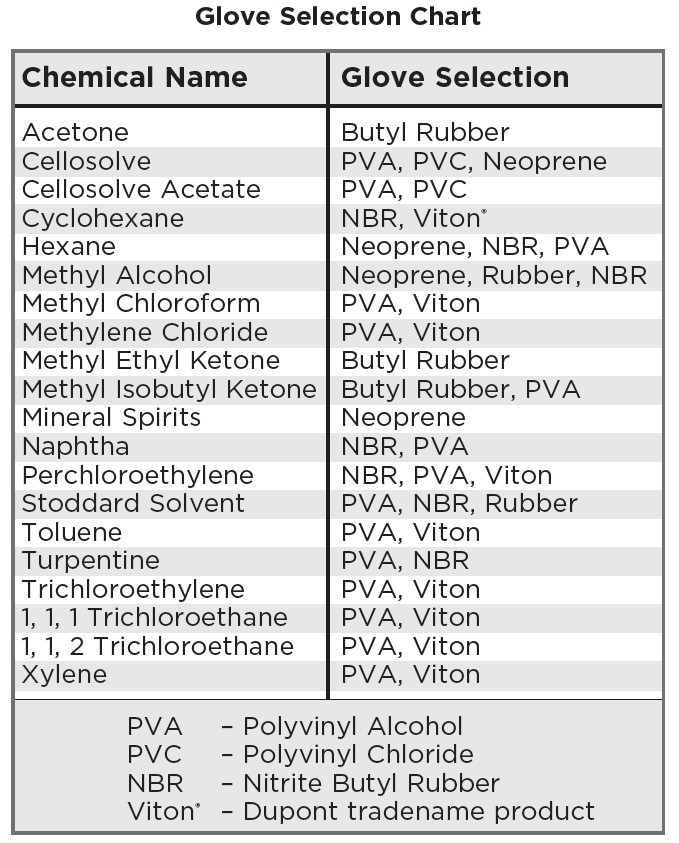

Our hands also need protection against chemicals. Check the label to see whether a product must be handled with gloves and what types of gloves are required.

If that information isn’t on the label, check the safety data sheet (SDS). An SDS must be available on site for any controlled products that are being used.

Using the right gloves for the job is important.

For instance, rubber gloves are no good with solvents and degreasers. The gloves will dissolve on contact.

Demonstrate

Talk about the specific chemicals used on your jobsite and the type of gloves recommended for each.

Use the SDS for reference or the Glove Selection Chart below.

For more information, visit the IHSA website.