Rigging Hardware

Rigging Hardware

Explain dangers

Rigging is only as strong as its weakest link. Workers’ lives depend on the strength of that link.

It doesn’t matter what safe working load is stamped on a hook if the hook is cracked and twisted or opening up at the throat. It can’t deliver its full rated capacity.

Inspection is vital in rigging and hoisting.

Identify controls

Rigging hardware must have enough capacity for the job. Only load-rated hardware of forged alloy steel should be used for hoisting. Load-rated hardware is stamped with its working load limit or WLL.

Adequate capacity is the first thing to look for in rigging hardware. For hoisting, the design factor must be 5 to 1.

Once the right hardware has been chosen for a job, it has to be inspected regularly as long as it’s in service.

There are warning signs that hardware has been weakened in use and should be replaced.

CRACKS

Inspect closely—some cracks are very fine.

MISSING PARTS

Make sure that parts such as catches on hooks, nuts on cable clips, and cotter pins in shackle pins are still in place.

STRETCHING

Check hooks, shackles, and chain links for signs of opening up, elongation, and distortion.

STRIPPED THREADS

Inspect turnbuckles, shackles, and cable clips.

Demonstrate

With your crew, inspect rigging hardware in use or stored on site. Repair or replace any damaged or defective items you find.

CABLE CLIPS

• Check for wear on saddle.

• Check that original parts are in place and in good condition.

• Check for cracks.

• Check for proper size of the wire rope.

SHACKLES

• Check for wear and cracks on saddle and pin.

• Check that pin is straight and properly seated.

• Check that legs of shackle are not opening up.

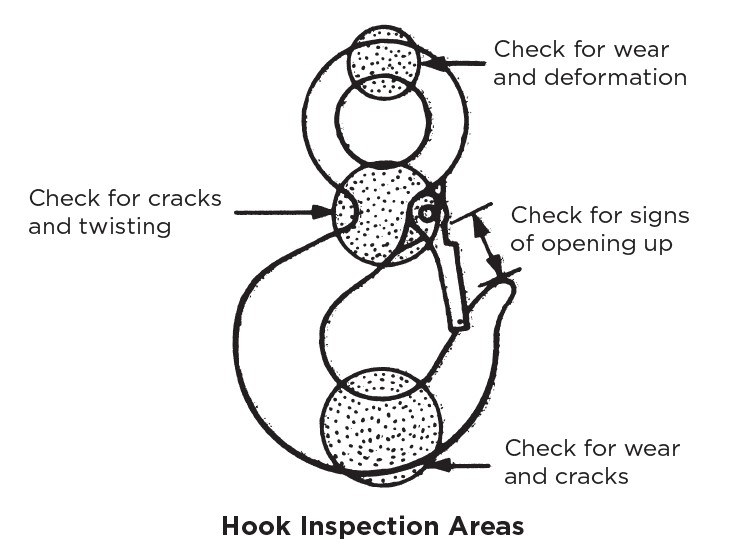

HOOKS

• Check for wear, twisting, and cracks.

• Make sure that hook is not opening up.

TURNBUCKLES

• Check for cracks and bends.

• Check rods for straightness and damage to

threads.

For more information, visit the IHSA website.