Suspended access equipment – Tiebacks

Suspended access equipment—Tiebacks

Explain dangers

Suspended access equipment (SAE) can fail if you don’t set up all of the components properly, such as tiebacks. Improper setup can lead to injury or death from a fall.

Identify controls

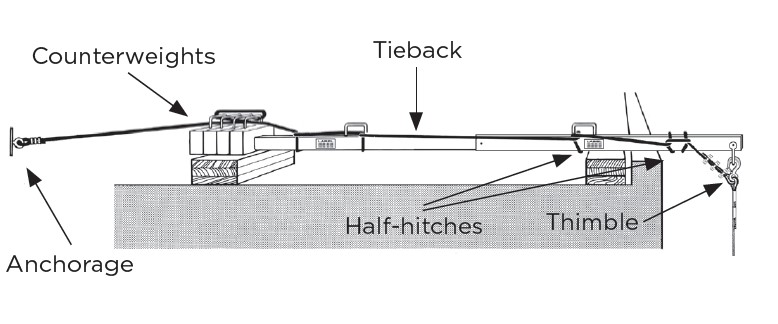

Tiebacks are used to secure the outriggers and counterweights of SAE. Wire ropes are recommended for tiebacks with all suspended access systems.

The tieback holds the major components of the suspension system together. It keeps them from being loosened or dislodged and secures them back to an adequate anchor point.

Let’s follow a wire rope tieback from start to finish.

• The tieback runs from the thimble of the suspension line back along the outrigger beam with at least one half-hitch on each section.

• Then it loops around the counterweight handles and extends back to the adequate anchorage.

Now let’s see how each part is connected.

1. Secure the wire rope tieback to the thimble of the suspension line with double saddle clips (also known as J-clips or fist grip clips). Cable

clips cannot be used with suspended work platform systems.

2. Make a half-hitch around the beam in front of the building facade.

3. Make a half-hitch through the handle on each section of the outrigger beam. Even if the beam doesn’t have handles, we still use the

half-hitches.

4. Make a half-hitch in front of the counterweights.

5. Run the tieback through and then back around the counterweight handles.

6. Attach the tieback to the anchor with the recommended number of clips. Make sure the tieback is taut.

Tiebacks must have the same rated strength as the primary suspension line. The wire rope used for tiebacks should be at least equal in size to the wire rope used for the SAE.

Any wire rope used for tiebacks should not be used for suspension lines afterwards because of damage and deformation from clips, bends, and hitches.

Adequate anchorage for tiebacks may include the following fixed supports:

• The base of large HVAC units

• Columns on intermediate building floors or stub columns on roofs

• Designed tieback systems such as eye bolts and rings

• Large pipe anchorage systems (12-inch diameter or greater)

• Roof structures such as mechanical rooms

• Davit arms/systems

• Parapet clamps attached to reinforced concrete parapet walls on the other side of the building.

A roof plan or design drawing approved by a professional engineer must indicate the proper anchor points for SAE.

Demonstrate

Demonstrate as you talk.

Point out the tiebacks and anchorages used on site.

For more information, visit the IHSA website.