Working at heights – Scaffolds – Planks and Decks

Working at Heights – Scaffolds – Planks and Decks

Explain dangers

Many scaffold injuries involve problems with planks. If scaffold planks and decks fail, you could be seriously injured or killed from a fall.

You could also be thrown off balance and injure yourself with your tools or equipment.

If scaffold planks are uncleated or unsecured, they can easily slide off. They can also break if they are in poor condition or overloaded.

If scaffolds are not fully planked, it can cause injuries not only during erection and dismantling but also during general scaffold use.

Identify controls

Use the proper grades of lumber and inspect planks before erection to ensure that there are no weak areas, deterioration, or cracks.

Inspect scaffold planks and deck material regularly. Here’s what to look for:

ON WOOD PLANKS

• Length — Planks must overhang the frame no less than 150 mm (6 in) and no more than 300 mm (12 in).

• Cracks — They can often be detected at the end of the plank. Discard planks with long and deep cracks.

• Cuts — Check plank edges for cuts from saws, tools, and sharp objects. Discard planks with many or deep cuts.

• Light weight — This can indicate dry rot that can’t be seen.

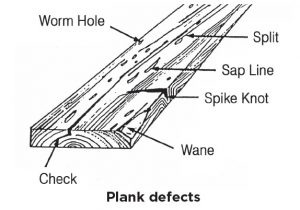

• Plank defects — Worm holes, splits, knots that are knocked out along edges, and lots of nail holes. Discard planks when defects are serious.

• Damaged cleats — They should be removed and replaced.

ON LAMINATED VENEER LUMBER PLANKS

• Separation of laminated layers — This is usually due to repeated changes in moisture levels as layers soak up the rain and then dry in the sun.

• Cuts of any kind.

• Pressure cracks in the top or bottom layer.

• Warping from wear and weather.

• Damaged cleats.

ON ALUMINUM/PLYWOOD DECK PANELS

• Cuts in aluminum frames.

• Deformed, cracked, or broken fastening hooks and hardware.

• Cracked or broken plywood.

• Bent, cracked, or broken rungs.

• Sliding or other locking devices in good condition.

• As a general rule, you should plank or deck the working levels of a scaffold across their full width for maximum support and stability.

Demonstrate

Demonstrate methods of inspecting planks and panels. Ask the crew to inspect sample materials on site.

For more information, visit the website.