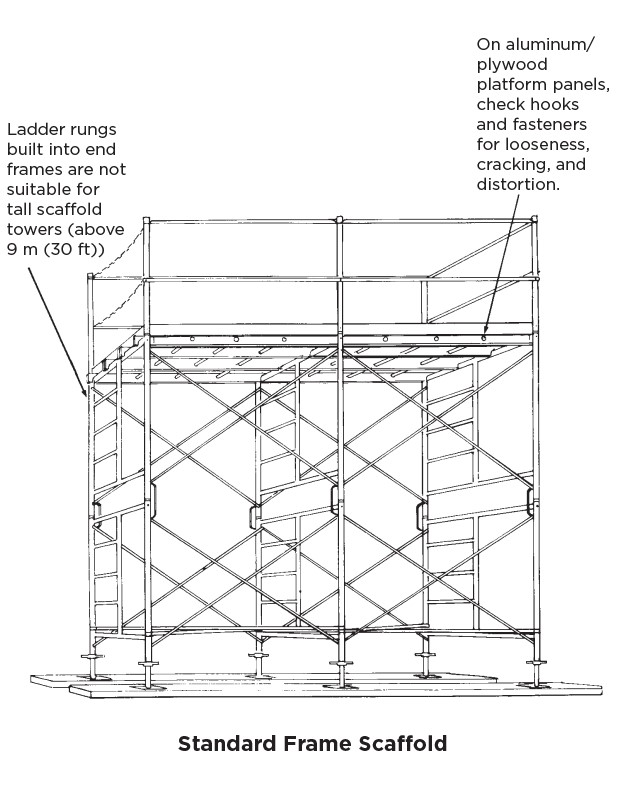

Working at Heights – Scaffolds – Structural Components

Scaffolds—Structural components

Explain dangers

If the structural components of a scaffold are damaged, defective, or installed incorrectly, it can lead to a tip-over or collapse.

Identify controls

Structural components of all frame scaffolds must be inspected regularly. Inspection should include frames, feet, connecting pins, braces, and guardrails.

FRAMES

• Uprights and cross-members should not be cracked, rusty, bent, or otherwise deformed.

• All connecting components should fit together square and true.

FEET

• Adjustable base plates should work properly.

• Plates should be securely attached to legs to resist uplift as well as compression.

• If mudsills are used, base plates must be nailed to them.

CONNECTING PINS

• Frames must be joined together vertically by connecting pins compatible with the frames.

• Connecting pins must be locked in place to prevent them from loosening and coming out.

• Pins must be free of bends and distortion. If they don’t fit, get replacements that do.

BRACES

• Cross and horizontal braces should not be cracked, rusty, bent, or otherwise deformed.

• Braces should be compatible with frames and free of distortion.

• Horizontal braces must be installed every third frame vertically and in each bay laterally.

• Scaffolds higher than three frames must be tied into the structure.

GUARDRAILS

• The work platform must have guardrails.

• Guardrails must be compatible with frames.

• Guardrails can be made of tube-and-clamp components if they’re assembled properly.

Demonstrate

As you talk, use a scaffold to demonstrate to your crew what to look for during an inspection.

For more information, visit the IHSA website.